Your productivity will increase with our future-proof pallet conveyor system

Pallet conveyor technology is an integral part of modern warehouse and production logistics. It includes various types of conveyor systems specifically designed to transport pallets and other heavy loads. These systems can be operated manually, semi-automatically or fully automatically and are suitable for a wide range of applications, from the simple transportation of goods from one location to another to integration into complex automated warehouse and production lines.

There are many benefits to using pallet conveyor technology. It can increase efficiency, reduce employee workload, improve material flow and increase safety in the workplace. It also enables better use of available space and can help reduce operating costs.

At Baust, we are a renowned supplier of pallet conveyor systems. With many years of experience in the industry, we offer a wide range of solutions tailored to the specific needs and requirements of our customers. Our Baust products are characterized by their high quality, reliability and durability.

Basics of pallet conveyor technology

Pallet conveyor technology is used in industry and logistics to facilitate the movement of pallets in a warehouse or production area. The main benefit of using this technology is the increase in efficiency. It allows pallets to be moved quickly and smoothly from one location to another, reducing manual labor and minimizing the risk of damage to goods. It also improves safety in the workplace, as it reduces the risk of accidents caused by manual handling of heavy loads.

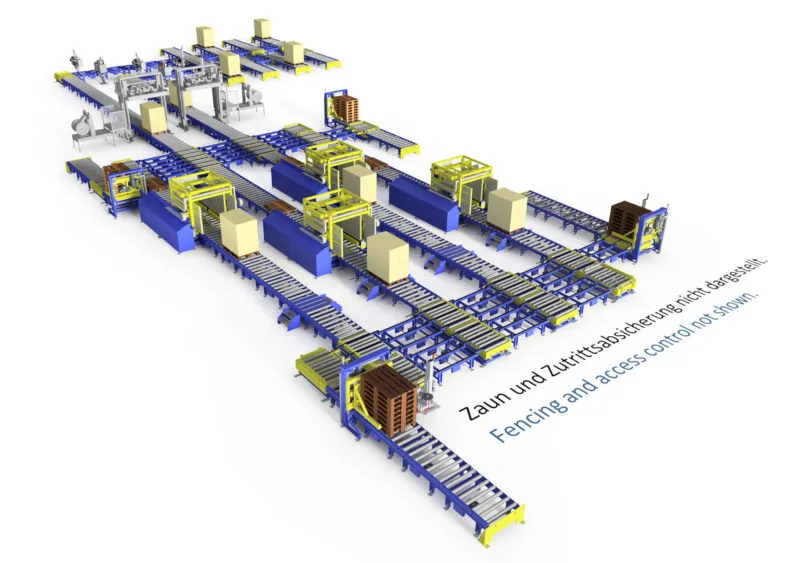

The operation of pallet conveyor technology can vary depending on the type of system. In general, however, a pallet conveyor system consists of a series of conveyor belts or roller conveyors arranged to form a continuous path for the transportation of pallets.

Regardless of the specific type of system, the basic principle of pallet conveyor technology is the same: a pallet is loaded onto the system, the system moves the pallet along the conveyor path and the pallet is unloaded at the desired location. This process can be repeated to ensure a constant movement of pallets within the warehouse or production area.

Customised pallet conveyor technology for your long-term business success

Every company has specific requirements for its material flow technology. We therefore develop our pallet conveyor technology individually according to your needs. A thorough analysis of your processes forms the basis for an optimally coordinated pallet conveyor system. Together, we develop solutions that sustainably improve your flow of goods.

The latest drive technology ensures that the pallet conveyor systems are energy-efficient to operate. The components used are characterised by low maintenance requirements. This minimises your operating costs while maintaining high system availability. Regular maintenance intervals also ensure long-term functionality.

Our experienced technicians support you from the planning stage right through to commissioning. Thorough training of your employees ensures smooth operation right from the start. The pallet conveyor system is thoroughly tested after installation. If required, we will also be at your side with service and support afterwards.

Your warehousing will benefit from well-thought-out pallet conveyor technology

Efficient warehousing requires well-thought-out logistics concepts. Our pallet conveyor system allows you to optimise the entire material flow in your warehouse. Automated storage and retrieval processes significantly accelerate the movement of goods. At the same time, the transparency of all logistics processes increases.

Intelligent control systems optimally coordinate all transport processes. The routing dynamically adjusts to the current order volume. The high-performance pallet conveyor system avoids bottlenecks and makes the best possible use of existing capacities. Your employees always have an overview thanks to clear visualisation.

Modern sensor technology continuously monitors all conveying processes. Potential faults are detected early and can be rectified preventively. This increases the operational reliability of your pallet conveyor system and reduces unplanned downtime. Your warehouse processes run reliably and efficiently.

Application examples for Baust pallet conveyor systems

Baust pallet conveyor systems are used in a wide range of industries and applications. Here are some practical examples of how companies use our systems:

- Food industry: in this industry, our pallet conveyor systems are used to automate processes.

- Automotive industry: By automating processes in the automotive industry, we can achieve greater speed and accuracy, resulting in improved productivity.

- Building materials industry: In this industry, our systems are used to handle and transport building materials. Our robust and reliable pallet conveyor systems can also handle heavy loads, making them ideal for this application.

- Pharmaceutical industry: In these industries, our pallet changers are used to automate the process of switching from one pallet to another. This increases efficiency and reduces operating costs.

Long-lasting quality makes our pallet conveyor system a safe investment

Investing in future-proof pallet conveyor technology is a long-term decision. High-quality materials and precise workmanship guarantee maximum durability. The pallet conveyor technology undergoes strict quality control before delivery. This consistent quality assurance pays off in the long run.

Modular design allows for later extensions without major expense. The pallet conveyor system grows flexibly with your future requirements. Existing modules can be easily integrated into new configurations. Your investment therefore retains its value even when conditions change.

Low maintenance and operating costs make the overall investment particularly cost-effective. The robust components of the pallet conveyor system work reliably even under heavy loads. Downtimes are reduced to a minimum thanks to the high quality of workmanship.

Automate your logistics with a flexible pallet conveyor system

Automation sustainably increases the efficiency of your logistics processes. Pallet conveyor technology enables a largely autonomous material flow. Intelligent control systems coordinate all transport processes. Manual intervention is limited to monitoring activities.

Conveyor technology can be easily integrated into existing warehouse management systems. Standardised interfaces enable real-time data exchange. Transport orders are automatically generated and optimally processed. The pallet conveyor system flexibly adapts to fluctuating capacities.

Comprehensive safety features protect people and materials. Modern sensor technology permanently monitors all movements. In case of faults, the affected areas are immediately shut down. Occupational safety is our top priority.

WORLDWIDE COMPANIES

that use pallets and trust Baust pallet changer & pallet turner