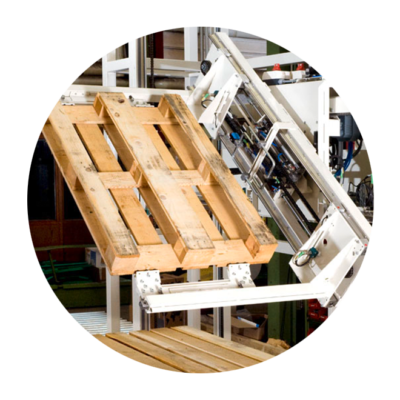

Pallet changer using the clamping method

Repalletizing robust goods fast and cheaply

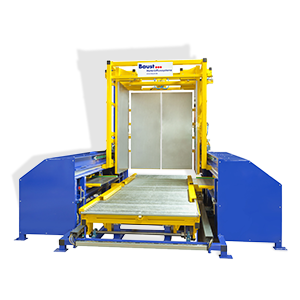

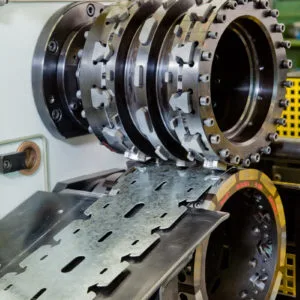

With the clamping method the load is firmly clamped from both sides. Then the pallet is lowered and can easily be replaced by a new one. This procedure is the simplest and most inexpensive way of pallet changing. The requirements: The goods have to be robust, pressure resistant and tightly stacked. The clamping method is perfect for the pallet changing of cartons or boxes. It is also often used for the changing of badly damaged pallets.

The clamping method is the simplest way of pallet changing and particularly suited for robust goods.

Clamping method: The simplest way to change pallets

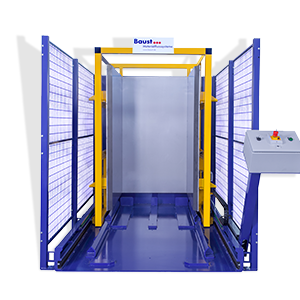

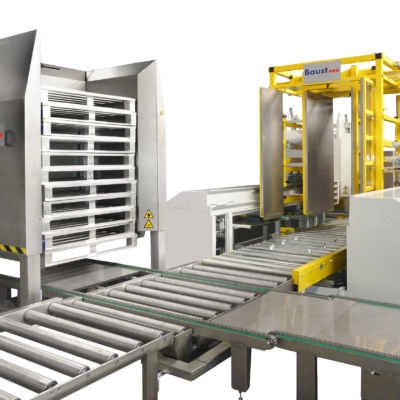

A pallet changer using clamping method can either work as a stand-alone element or be integrated into a material flow system. The exchanger is loaded and unloaded via manual or electric pallet truck. Side walls clamp the load and then the pallet will be lowered by the pallet truck. Now the pallets can be changed fast and easy. Integrated in a material flow system the pallet changing is done by a lift conveyor. The clamping method neither inverts or tilts the load.

Pallet changer using the clamping method

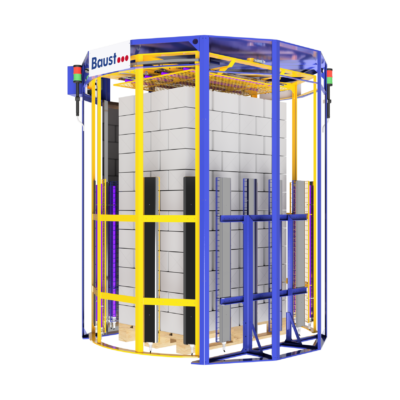

The clamping method is particularly suitable for goods that are stable under pressure and stacked squared up without gaps. This type of pallet changer convinces with its low price and its easy application. The clamping walls grip the stacked goods from two sides and fix them. Then the pallet is lowered and removed. So it can easily be replaced by any other load carrier. This procedure is recommended for the pallet exchange of insensitive goods such as cardboard boxes, beverage boxes or crates. They are moved in with an electric or pallet truck. Alternatively, the pallet handling can be designed fully automatically using a conveyor line.

The modern and robust pallet changers from Baust material flow systems can make up to 50 changes per hour. The changers can also be easily integrated into fully automatic conveying systems. With the clamping process, you can exchange any pallet: whether from Euro pallets to plastic pallets for the hygiene sector, space-saving Düsseldorf pallets in retail or one-way pallets for transport abroad – the Baust pallet changer does the job quickly and reliably for you.

Products using the clamping method

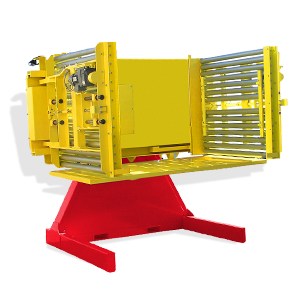

Pallet changer

PW 500

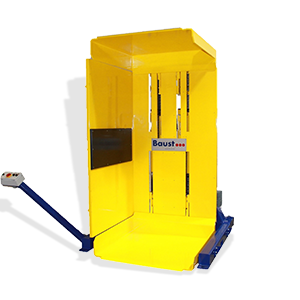

Pallet changer

PW 500 Inline

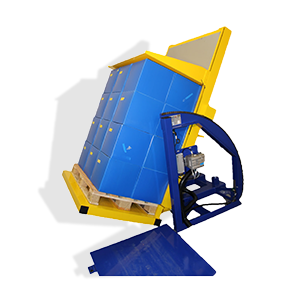

Pallet inverter

PW 600

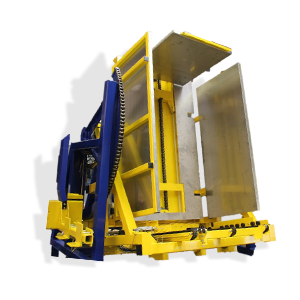

Pallet inverter

PW 600 Inline

Pallet inverter

PW 700

Pallet changer

PW 800 E

Pallet changer

PW 800 C

Pallet changer

PW 800

Pallet changer

PW 800 Inline

Pallet changer

PW 900 Inline

Pallet changer

PW 1000

Pallet changer

PW 2000

Pallet changer

PW 3000

Pallet changer

PW 4000

Pallet changer

PW 5000

Pallet changer

PW 6000

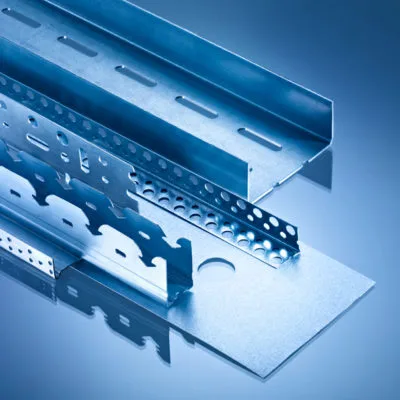

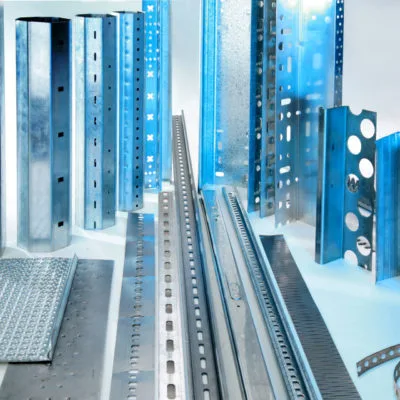

Construction Metal Industry

Pallet handling

Pallet transport

Drum handling & transport

Mesh boxes

Long goods transport

Container transport

Digital printing

Electro Industry

Shelf and storage technology

Roller blinds

Data protection - privacy policy

Are you looking for an inexpensive pallet changer for robust goods? Then we recommend the clamping method. Here, the goods are firmly fixed on two sides when changing the pallet, while the pallet is lowered by a pallet truck or lifting roller conveyor and then exchanged. Our pallet changers in the clamping process can be used as free-standing stand-alone elements as well as integrated in material flow systems.

You can manage up to 50 pallet changes per hour. These inexpensive clamp pallet changers are particularly suitable for poor pallet quality. These palletizers are ideal for goods in boxes or crates, as well as any goods that are pressure-stable and packed without gaps. It does not matter how high the pallet is loaded. The goods only have to withstand the pressure of the side arms.

Space-saving and easy to use

The pallet changer with the clamping method takes up little space and is easy to use. It is loaded by hand pallet truck or with an electric pallet truck. By replacing inferior pallets, you save yourself trouble in later work processes, especially with automatic systems. In the food and pharmaceutical industries, particularly high-quality pallets are often prescribed for hygienic reasons. With the Baust pallet changer in the clamping process, you can do the pallet change quickly, space-saving and uncomplicated. Call us and we recommend the pallet changer that fits your individual requirements exactly!

Our models for your application

Changing the pallet with our devices using the clamping method saves you a lot of manual work and ensures a quick and uncomplicated workflow. Our inexpensive PW 500 pallet changer, for example, is the first choice if you want to re-palletize boxes or tightly packed boxes using the clamping process. It can move up to 1000 kg weight and a maximum height of 2000 mm including the pallet. The pallet changer has a size of 2100 x 3300 x 2300 mm and weighs a total of 1500 kg. Between ten and 25 changes per hour can be achieved with this device.

PW 500 Inline Pallet changer

The PW 500 Inline can be integrated into fully automatic material flow systems. 30 to 50 changes per hour are no problem for this pallet changer in the clamping process. With the dimensions of 2300 x 3300 x 2800 mm and a machine weight of 2000 kg, it fits well into any fully automatic system. The PW 500 Inline can process a total weight of 1000 kg and a height of 2000 mm including the pallet. As a special version, we also offer higher product heights, further pallet widths, a hydraulic version and the side walls in a hygienic version. So you get the model that exactly matches your requirements!

Master the clamping method now!

Request a non-binding inquiry