Pallet Tipper: Inverting and tilting method pallet changer | Pallet upender

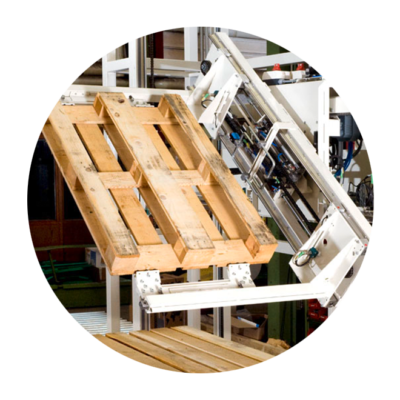

Pallet changers using the tilting and inverting method are particularly suitable for sacks, drums or overhanging goods – so whenever the goods are insensitive but not very stable. These machines, called pallet tipper can easily handle different pallet sizes and poor pallet quality.

Up to 40 pallets can be changed per hour. In the tilting process, two side walls fix the goods. Then the palletizer tilts backwards up to 135 °. The pallet can be individually tilted back and easily replaced at floor level.

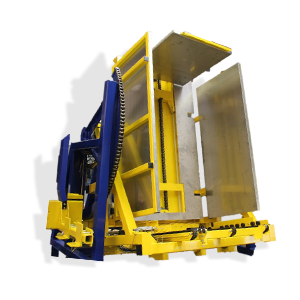

Both methods resemble each other and can therefore be mentioned in the same breath: Pallet changers using inverting method (so called pallet inverters) and pallet changers using the tilting method, tilt the load to a certain angle.

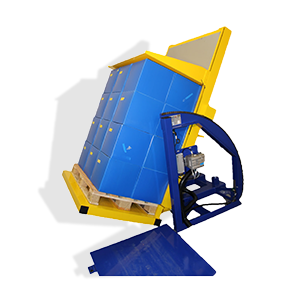

The differences between the two techniques: Pallet inverters rotate the goods 180 degrees. This means that the load is turned upside down. Pallet changers using tilting method, however, turn the loaded pallet backwards only 92 to 135°. Both methods are normally used for robust goods, such as sacks, drums or cardboard boxes. They are also ideal for the pallet changing with overhanging load.

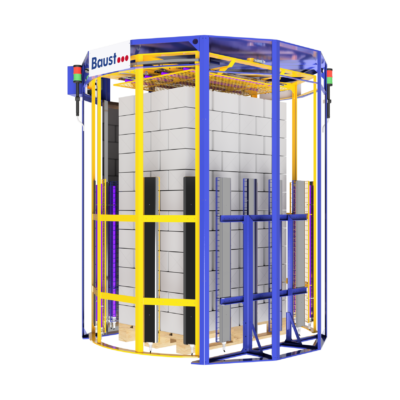

Pallet changer in the inverting process: The goods are turned upside down.

Palletizing with the right turn

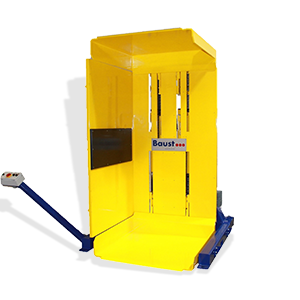

In the case of a pallet changer using the inverting method, the loading is carried out with a forklift or pallet truck, depending on the model. The pallet is held from 3 sides and then rotated by 180 °. The pallet lies on the goods and can be exchanged very easily. Then the pallet changer turns everything back by 180 °. In some industries, the orientation of the goods is unimportant. Then the target pallet can be placed directly on the goods and the goods are literally upside down after just one turn.

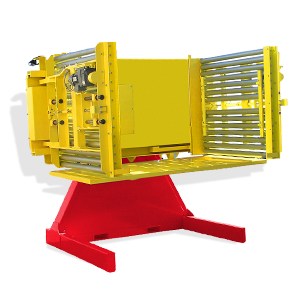

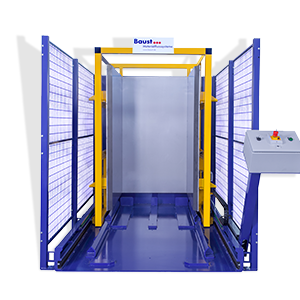

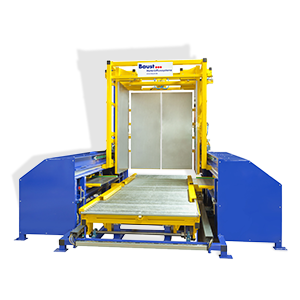

Pallet changer in the tilting process: The goods are tilted backwards 92 – 135°.

Pallet changers with the tilting process

Pallet changers with the tilting method are loaded and unloaded using a pallet truck or forklift – conveniently at floor level.

Two side walls fix the goods and tilt them backwards up to 135 °. Now the pallet is tipped back separately and can be replaced ergonomically without manual pallet handling.

Process of the tilting method

The pallet can be ergonomically exchanged at floor level.

If the goods are insensitive, but less dimensionally stable, a pallet changer with tilting or inverting method is often used. The pallet changer is suitable for sacks as well as for drums or big bags and other goods with an overhang. Whether a inverting pallet changer or a tilting pallet changer is more suitable for your needs depends on your individual requirements. We are happy to help!

The pallet changer with inverting method, the pallet is held on three sides. The entire stack is turned upside down by 180 degrees. So the pallet – which is now on top – can be easily replaced. In industries where the orientation of the goods is not important, the new pallet can be placed on the goods beforehand and the entire stack can be taken out directly after inverting with the pallet inverter. With this variant, only the old pallet then has to be lifted off. In addition, there is also the option of moving only a 95 ° turn in order to then easily replace the empty pallet in the vertical position. The pallet inverter from Baust combines maximum flexibility with simple and robust technology.

In the pallet changer tilting method, two side walls and a top plate fix the goods and tilt them backwards by up to 135 °. The empty pallet moves down again for the change and can be replaced ergonomically at floor level. Then it is swiveled back onto the goods and tilted back with the load into the starting position.

Both types of pallet turner can be loaded and unloaded using a pallet truck, a forklift (PW stand-alone) or a fully automatic conveyor system (PW Inline). They change up to 40 pallets per hour.

Free initial consultation & technical planning

- Kostenfreie Planung der definierten Spezifikationen

- Free planning of the defined specifications

- Fast, clean and binding development

- Non-binding offer and detailed documentation

- Technical expertise right from the start

- Consulting, planning, production, assembly and maintenance from a single source without subcontractors

Pallet changers using the inverting and tilting method | Pallet upender

Pallet changer

PW 500

Pallet changer

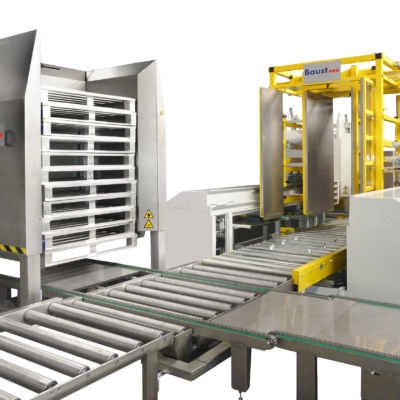

PW 500 Inline

Pallet inverter

PW 600

Pallet inverter

PW 600 Inline

Pallet inverter

PW 700

Pallet changer

PW 800 E

Pallet changer

PW 800 C

Pallet changer

PW 800

Pallet changer

PW 800 Inline

Pallet changer

PW 900 Inline

Pallet changer

PW 1000

Pallet changer

PW 2000

Pallet changer

PW 3000

Pallet changer

PW 4000

Pallet changer

PW 5000

Pallet changer

PW 6000

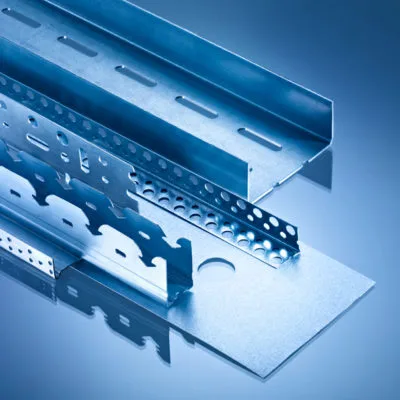

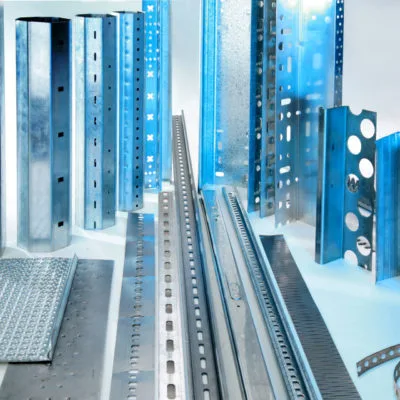

Construction Metal Industry

Pallet handling

Pallet transport

Drum handling & transport

Mesh boxes

Long goods transport

Container transport

Digital printing

Electro Industry

Shelf and storage technology

Roller blinds

Data protection - privacy policy

Pallet tipper/ Pallet upender: Here the goods are upside down

In the inverting process, the goods are held from three sides and turned by 180 °, i.e. turned upside down. As a result, the pallet is now on the goods and can be replaced very easily. If necessary, damaged goods can be removed from the bottom layer of the stack after the first turning process. Then the entire stack is turned back. If the orientation of the goods is unimportant, the target pallet can also be placed directly on the goods and the stack can be further processed after inverting once. Baust offers both the tilting and turning processes as free-standing stand-alone machines and for installation in material flow systems. They can be loaded and unloaded using a pallet truck and forklift. Call us and we recommend the pallet changer that fits your individual requirements exactly!

Our models for your application

The PW 600 is suitable for uncomplicated palletizing in the inverting process. This pallet changer processes pallets in various sizes between 800 and 1000×1200 mm and a total weight of up to 1500 kg. The height can be between 500 and 2000 mm. This rotating pallet changer manages 10 to 20 changes per hour. Automatic control and access protection are available as an option. Customers particularly appreciate our PW 600 in a small space. The PW 600 Inline is available for fully automatic conveying systems and can palletize up to 1500 kg in weight from 1000 to 2000 mm.

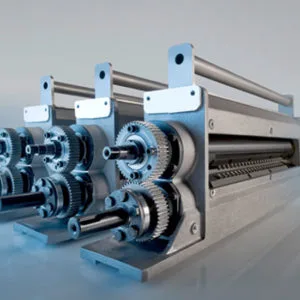

Pallet changers with the tilting method

The PW 800 model series works in a tilting process, which is available both as a stand-alone model and for use in conveying systems and in an economy version. This PW 800 E comes without side walls and pallet clamps and is suitable for tilting-resistant goods. All of these tilting pallet changers run with a low-maintenance, low-noise electric drive without the risk of leakage. As a special feature, the pallet changer can also process different pallet sizes and goods heights over two meters using the tilting method. Different centering options are also possible. In addition, a loading table with a lifting mechanism is available for this pallet changer in the tilting process.

Master the inverting and tilting method now!

Request a non-binding inquiry