Pile turner

Safe pallet changing in every branch of industry

Do you want to optimize the productivity of your stacks? Then a Pile Turner from Baust is the ideal solution for you! With our innovative devices, you can effortlessly rearrange your stacks, significantly increasing the efficiency of your material flow. By using a Baust Pile Turner, you reduce not only time expenditure but also operating costs. All of our Pile Turners are manufactured according to the strictest quality criteria and offer you a reliable and durable solution for your requirements. Benefit from our expertise and further optimize your logistics processes!

Rely on our experience and make your logistics processes even more efficient!

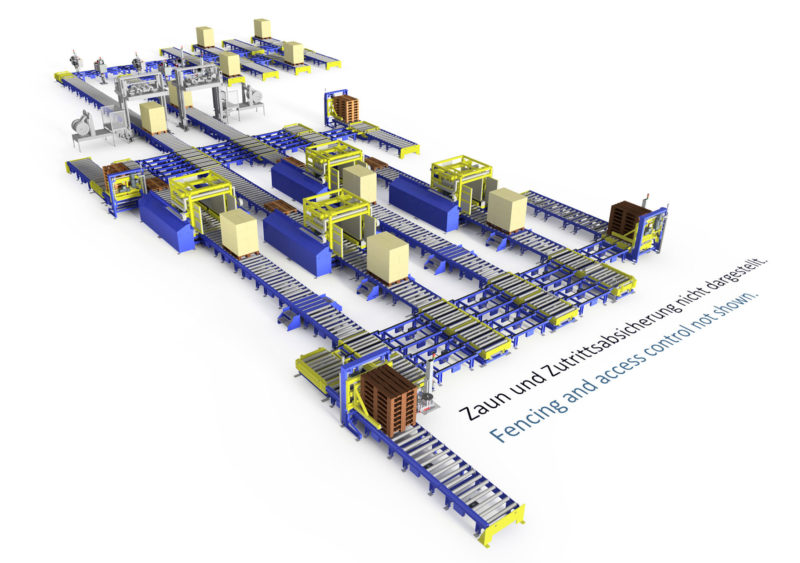

Repalletize processes with a pile turner machine

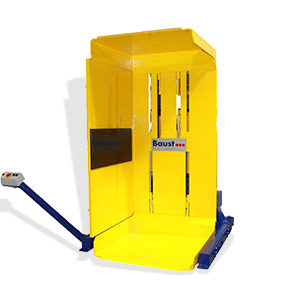

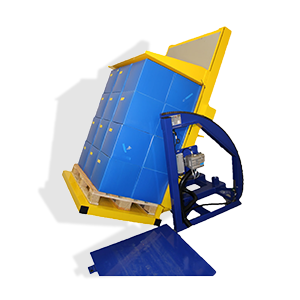

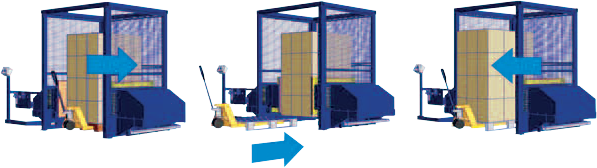

Pile turners with the clamping method

Palletize robust goods quickly and cheaply

- Side clamping of the goods

- Simplest and cheapest option for particularly robust goods

- pallet inverting: Ideal for palletizing cardboard boxes and boxes

- Lowering and exchanging the pallet using a hand pallet truck or a lifting roller conveyor

- Performance: up to 50 changes per hour

Pallet changer <br/>PW 500

Pallet changer <br/>PW 500 Inline

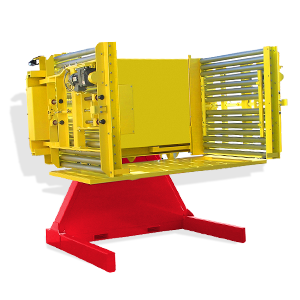

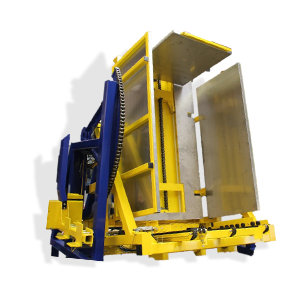

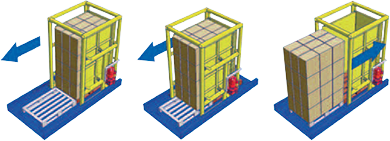

Pile turner machine with the inverting and tilting method

Suitable for many pallet sizes

- Rotate or tilt the goods by 90 to 180°

- Ideal for palletizing sacks and big bags

- Overhang of the goods is not a problem

- Reliable even with poor pallet quality and different pallet dimensions

- Performance: up to 55 changes per hour

Pallet inverter <br/>PW 600

Pallet inverter <br/>PW 600 Inline

Pallet inverter <br/>PW 700

Pallet changer <br/>PW 800 E

Pallet changer<br/> PW 800 C

Pallet changer <br/>PW 800

Pallet changer <br/>PW 800 Inline

Pallet changer <br/>PW 900 Inline

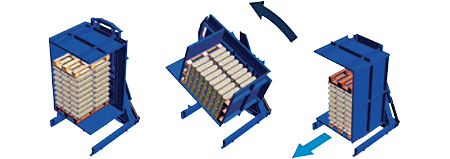

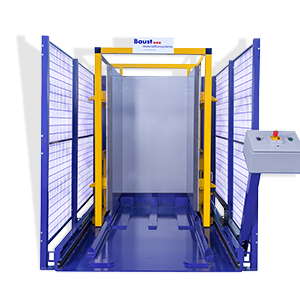

Load turner and the reverse method

The reverse method of a stack turner works as follows:

- Loading the pallet: the pallet is loaded into the pile turner, either manually by a forklift or automatically by a conveyor belt.

- Securing the load: once the pallet is loaded, it is secured by a hydraulic clamp or pressure plate mechanism. This mechanism holds the pallet and its load securely while the turning operation takes place.

- Turning operation: After the load is secured, the turning operation begins. The pile turner machine lifts and rotates the pallet 180 degrees. Depending on the model and settings, this process can be repeated once or several times.

- Unloading the pallet: After the pallet has been turned, the securing device is released and the pallet can be removed from the pile turner.

This method makes it possible to bring the bottom of the pallet up or replace damaged pallets without having to manually dismantle and reassemble the entire load. It improves efficiency and safety in the warehouse and reduces the risk of injury from manual handling.

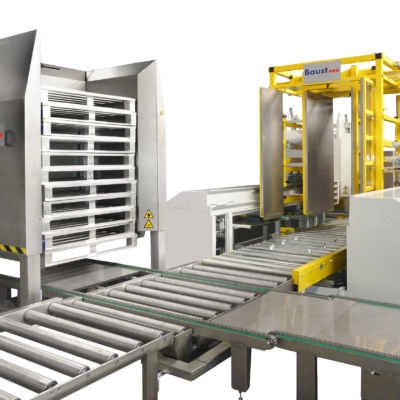

Pallet changer <br/>PW 1000

Pallet changer <br/>PW 2000

Pallet changer <br/>PW 3000

Pallet changer <br/>PW 4000

Pallet changer <br/>PW 5000

Pallet changer <br/>PW 6000

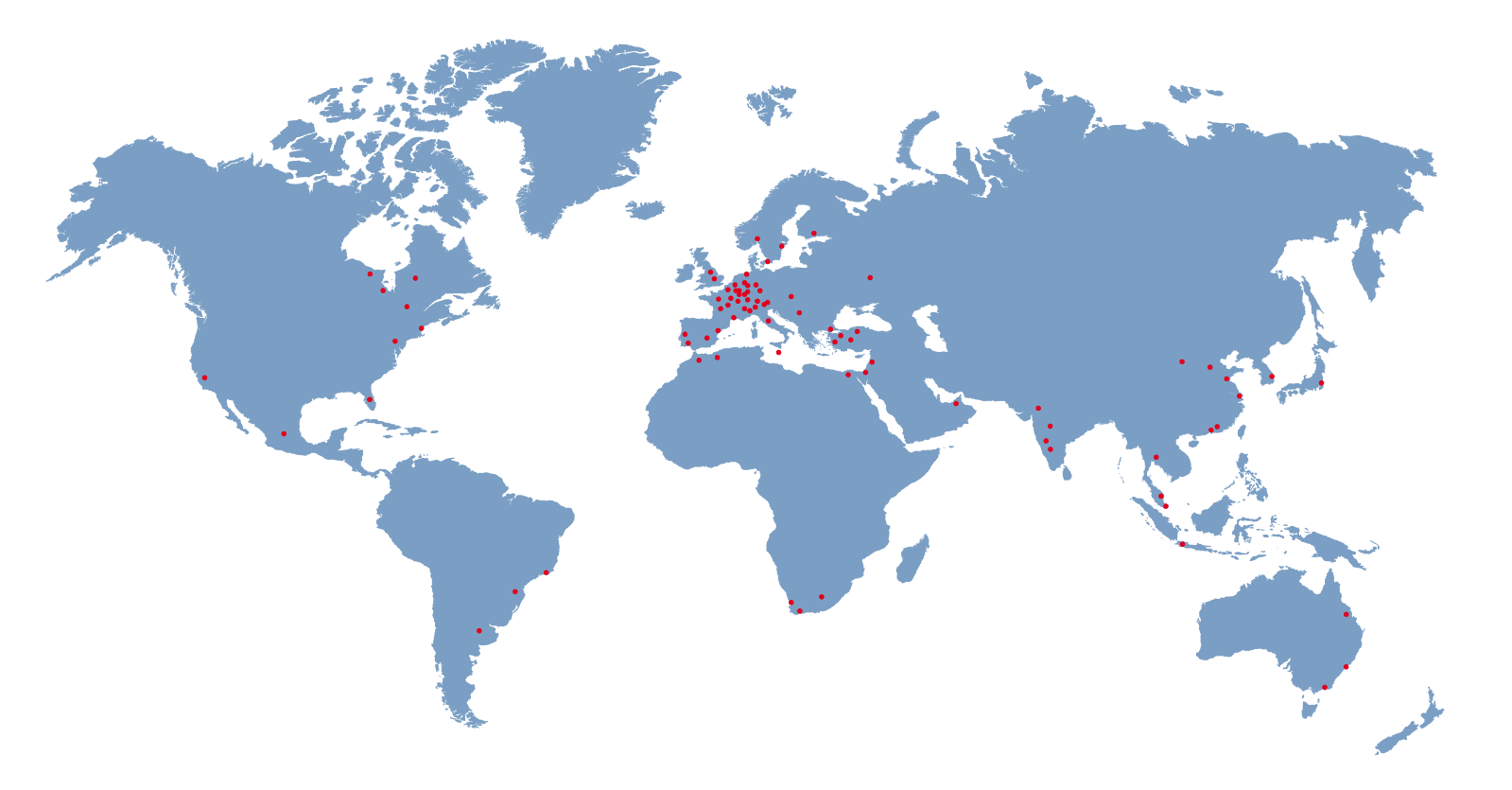

GLOBAL COMPANIES

who trust in Baust pallet changers

Maximize Your Storage Space with Baust’s Pile Turners

In modern warehouses and production facilities, efficient space utilization is crucial. Our pile turners offer the perfect solution to optimize your valuable storage space. These innovative devices allow you to stack and turn pallets and other load carriers in a space-saving manner.

By using our pile turner machines, you can fully exploit the vertical dimension of your warehouse. Instead of only storing goods horizontally, you effectively utilize height with our equipment. This leads to a significant increase in your storage capacity without requiring additional floor space.

Our stack turners are designed to seamlessly integrate into existing storage systems. They can easily maneuver between rows of shelves and place goods in hard-to-reach locations. This not only optimizes space utilization but also improves the flow of goods in your warehouse.

Another advantage of our load turners is their versatility. They are suitable for various types of load carriers and goods. Whether heavy pallets or sensitive items – our pile turners handle them all with precision and care. This flexibility allows you to dynamically adapt your warehouse to changing requirements.

The Benefits of Our Modern Pile Turners for Your Business

Our pile turners offer your company a multitude of benefits that go far beyond mere space optimization. A main advantage is the significant time savings in storage processes. By efficiently handling goods, you reduce the time your employees need for restacking and rearranging. This leads to increased productivity throughout your entire warehouse operation.

Furthermore, our pile turner machines contribute to improving workplace safety. They minimize the need for manual lifting and carrying of heavy loads, significantly reducing the risk of injuries and overexertion for your employees. This not only has positive effects on your team’s health but also reduces potential downtime and associated costs.

Another significant advantage is the protection of your goods. Our stack turners treat your products with the utmost care. Through precise movements and gentle handling, the risk of damage is minimized. This is particularly valuable for sensitive or high-value goods where integrity is of utmost importance.

Investing in our modern pile turners also pays off in the long term. Due to their robust construction and high-quality materials, they are characterized by a long service life. This reduces maintenance and replacement costs and ensures high profitability of your investment.

Why Pile Turners Are Indispensable for Your Logistics

In today’s fast-paced business world, efficient logistics is the key to success. Our pile turners play a central role and have become indispensable in modern logistics processes. They form the backbone of a smooth flow of goods and contribute significantly to optimizing your entire supply chain.

A main reason for the indispensability of pile turner machines in logistics is their ability to accelerate processes. They enable fast and precise rearrangement of goods, which is invaluable, especially in just-in-time deliveries or e-commerce. By reducing waiting times and bottlenecks, our load turners ensure a continuous and efficient material flow.

Moreover, stack turners increase the flexibility of your logistics processes. You can quickly react to changes in order situations or inventory levels. This adaptability is crucial in a dynamic market environment and gives your company a clear competitive advantage.

Another aspect that makes pile turners indispensable is their role in quality assurance. The gentle handling of goods minimizes the risk of transport damage. This is particularly important for sensitive or high-value products where perfect condition is crucial for customer satisfaction.

Improve Your Work Processes by Using Pile Turners

Integrating our pile turners into your work processes leads to significant improvement and optimization of your operational procedures. Through their versatile applicability and high efficiency, they contribute to simplifying and accelerating work steps.

A central aspect of process improvement through pile turner machines is the reduction of manual interventions. Tasks that were previously time and personnel-intensive can now be quickly and precisely taken over by our devices. This not only relieves your employees but also reduces errors that can occur through manual handling.

Our stack turners also enable more flexible design of your work processes. They can quickly switch between different tasks, which is particularly advantageous in environments with changing requirements. This adaptability helps to minimize idle times and increase the overall efficiency of your operation.

Another important aspect is the improvement of work ergonomics. The use of load turners reduces physically strenuous activities, leading to improved working conditions for your employees. This not only has positive effects on the health and satisfaction of your team but can also contribute to a reduction in illness-related absences.

Increase Your Competitiveness with Pile Turners

In a fiercely competitive market environment, the use of our pile turners can give your company a decisive competitive advantage. These innovative devices contribute to increasing your operational efficiency and optimizing your cost structure.

A key factor in enhancing your competitiveness through pile turner machines is the increase in productivity. By accelerating storage processes and optimizing the flow of goods, you can process more orders in less time. This allows you to react more flexibly to customer wishes and shorten delivery times – a decisive advantage in today’s fast-paced business world.

Furthermore, our stack turners contribute to cost reduction. By optimizing warehouse utilization and reducing manual work steps, you can significantly reduce your operational costs. You can use these savings to offer more competitive prices or invest in other areas of your business.

Another aspect that strengthens your competitiveness is the improvement of quality control. Our load turners enable gentler handling of your goods, leading to a reduction in damage and an increase in product quality. This, in turn, contributes to increasing customer satisfaction and strengthens your position in the market.

By using cutting-edge technology in the form of our pile turners, you also position your company as an innovative and future-oriented player in your industry. This can give you an edge over competitors who still rely on older or less efficient methods.