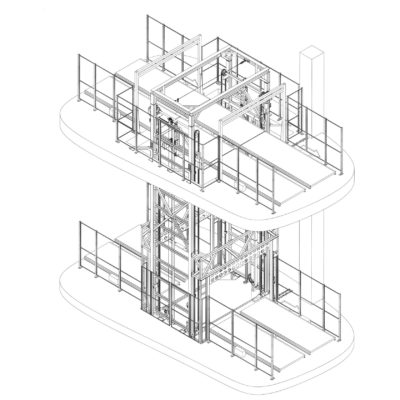

Baust’s fitters had to work high up in two projects at once: in Poland and the Netherlands, vertical conveyors were installed in the area of corrugated cardboard logistics. The challenge: 2.4 metre high corrugated cardboard stacks, 3 x 4 meter wide or long and weighing up to 3.2 tonnes, are to be moved up to ten meter in height. An output of up to 60 cycles per hour is required. The stable and robust design of Baust’s welded steel constructions are the ideal solution here.

Vertical conveyors can lift up to five tonnes

Our engineers have installed a belt or chain conveyor on the lifting platform, adapted to the requirements, to ensure gentle and safe transport. A drive power of 15 to 20 kW ensures that up to five tonnes of payload can be moved without any problems.

It was exciting to bring the vertical conveyors into the buildings and assemble them on site. The pillars, which were up to 13 meter long, were split several times and skilfully erected and assembled on site.

Safe operation of the vertical conveyors

Access protection is provided on each level by fencing, safety light barriers and high-speed doors. For free-standing vertical conveyors without shaft installation, complete enclosure is even possible as an option. A brake safety device on the lifting platform provides additional safety. But “safety first” also applies in the event of maintenance or malfunctions: Maintenance in the upper area is carried out in a space-saving and ergonomic manner via the accessible lifting platform. A rope system including a height safety device is suspended inside the vertical conveyor for this purpose.

Have we aroused your interest? Feel free to contact us to plan your vertical conveyor: